TFP manufacture a range of aramid nonwovens which offer an inherent resistance to abrasion. This property is exploited in applications such as industrial roll coverings or friction product substrates, where enhanced wear resistance is required.

Our aramid materials demonstrate excellent resin uptake and are compatible with most common composite resin systems, making them suitable for use in all major composite fabrication techniques. Some key applications for these materials are:

- Imparting superior wear resistance to the surface of high speed industrial rollers used in printing, textiles and papermaking. The aramid can also be blended with conductive fibres to provide protection from surface static discharge.

- Providing an excellent substrate for friction products; TFP’s nonwovens have been used as an effective coating base for automotive clutch, brake and transmission system parts.

- Creating a more wear resistant surface finish, an important consideration in the manufacture of composite sporting goods, where it can increase the product resilience and life span.

A NEW STUDY:

A recent study carried out in-house indicates that the use of an aramid nonwoven as a surfacing veil significantly improves the abrasion resistance properties of the resulting composite structure.

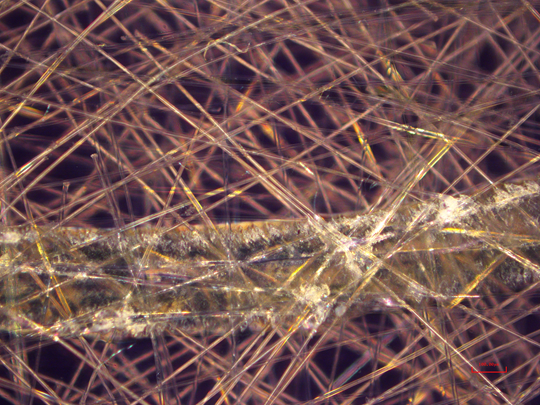

Aramid is high performance synthetic material which exhibits good resistance to abrasion. A study has been conducted which demonstrates that the inclusion of a lightweight aramid surfacing veil protects the underlying composite lay-up, acting as both a durable and sacrificial layer. Without the inclusion of the aramid surface veil the findings indicate that the composite is damaged much more easily.

The micrograph on the right shows a wear test carried out on a composite part containing an aramid surface veil. Very little damage has occurred to the composite as a whole and no damage has occured to the underlying structural element (in this case a woven carbon). The aramid veil on the surface acts as a sacrificial layer, remaining largely intact and protecting the rest of the composite structure from wear.

THE RESULTS:

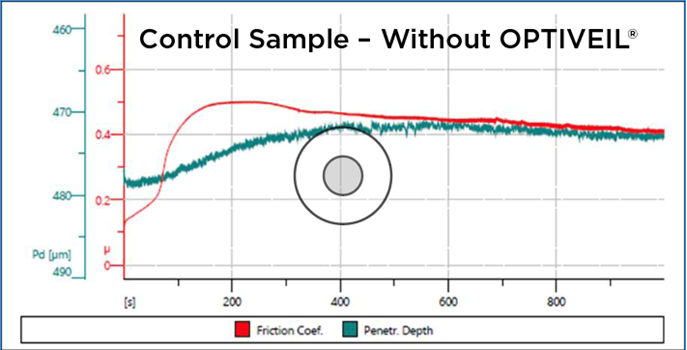

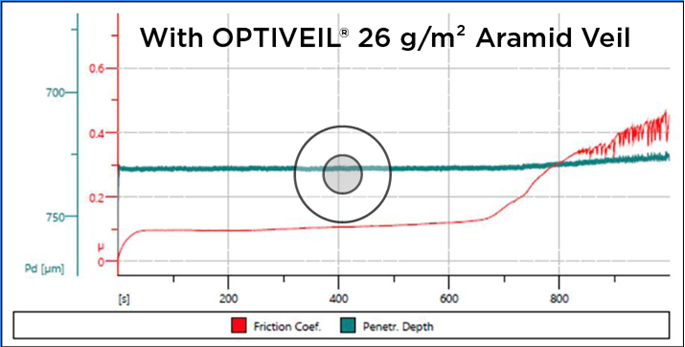

A number of composite samples were fabricated using woven carbon fibre plies, epoxy resin and (with the exception of a control sample) a surfacing veil. The properties of these samples was then tested using a pin-on-disk tribometer* which is used to measure friction and wear, and the measured coefficient of friction was plotted against time. The graphs for both the best performing sample (26g/m² aramid surfacing veil) and worse (control - no surfacing veil) are shown below. The data indicates that the inclusion of the aramid veil significantly increases the time taken for the wear test to progress through the sample. The coefficient of friction stays low and it takes 5 times as long for the friction to plateau out to the same value as the control sample. Essentially, this indicates that the use of a surfacing veil means that the level of friction experienced is lower and therefore significantly less material is worn away.

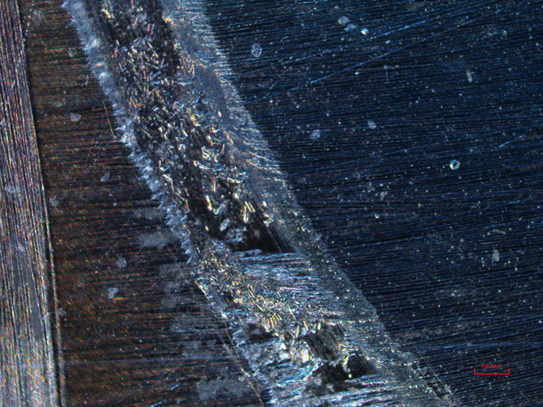

The samples were then inspected to visually assess the damage to the surface and underlying reinforcement. A range of different surface veils were trialled including; 10 & 17g/m² glass, 8 & 17g/m² polyester and 14 & 26g/m² aramid. Of these, the aramid veils performed best with evidence of just surface fibre damage (rather than breakage for glass & polyester) and, in the case of the 26g/m2 aramid, no exposure of the carbon weave. In all samples except the control, the carbon weave remained undamaged. Images of the best and worst performing samples post-test are below.

Control Sample (Without OPTIVEIL) - surface fibre breakage and carbon weave exposed & damaged.

With OPTIVEIL 26 g/m² Aramid Veil - no surface fibre breakage and carbon weave is not exposed or damaged.

*The tribometer parameters used were: ball diameter 6mm, wear radius 5mm, load 10N, speed 240 rpm and a duration of 4000 cycles.