TFP’s conductive nonwovens provide an effective, lightweight and practical solution for imparting EMI shielding functionality to composite components such as avionics enclosures.

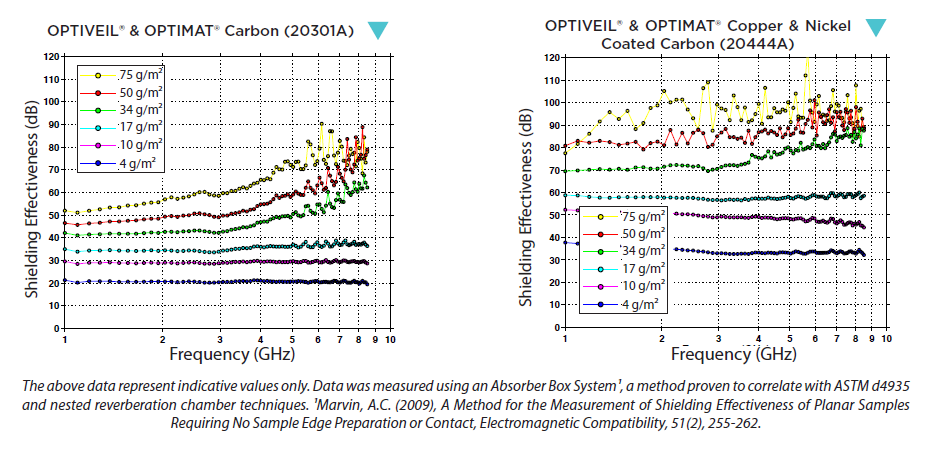

The shielding effectiveness can be custom designed to meet the requirements of the application by selecting fibre type, metal coating and areal weight. The shielding effectiveness of a carbon and copper & nickel coated carbon nonwoven at 1-8.5 GHz is:

TFP’s carbon, nickel coated carbon and copper & nickel coated carbon nonwovens are both lightweight and compatible with composite, automotive and aircraft assembly techniques. They provide EMI shielding that meets or exceeds that of difficult to handle metal meshes and offer several key benefits:

- Shielding effectiveness can be tailored to meet the requirements of the application by selecting fibre type, metal coating and areal weight.

- Lightweight (from 4 g/m2) & thin - providing excellent shielding effectiveness relative to weight.

- Flex fatigue resistance and conformable to complex shapes.

- Ease of use - veil has high porosity and exceptionally uniform fibre dispersion to ensure even resin uptake in composites.

They also have a diverse range of applications, including:

- Electronics & avionics enclosures

- Battery housings

- Motor & actuator housings

- Composite panels & enclosures

- Mobile phones

- Resistive heating

- Medical devices

- Conductive tapes